What an achievement, this is my (Christopher Roberts’s) 100th post on Technology Bloggers!

Thank you everyone for your support, I love writing here, and that is because of the fantastic community we have created 🙂

3D printers have been around for around 20 years now, however it is only recently that they have really started to show their true potential, both in industrial and now even domestic settings.

Thanks to the recent advancements in 3D printing, CAD designs can be constructed into physical prototypes (and in some cases now even final products) by 3D printers. 3D printers have the potential to revolutionise the way we live our lives, due the variety of possibilities they unlock. 3D printing could revolutionise architecture, product design, industry, education, and so much more!

What exactly is 3D printing?

Most people have access to a normal printer, be it black and white or colour, ink jet or laser. Those sorts of printers however, only work in 2 dimensions, they can print content in the dimension that is left to right, and the dimension that is forward to back. 3D printing adds in another dimension, up and down. Therefore 3D printing means that you can print in height, length and breadth.

Why is 3D printing important?

Some critics have speculated that 3D printing will be as big, if not a bigger revolution to industry, and the way we live our lives, than the internet was. The internet has opened up so many opportunities, but it is believed that 3D printing, could possibly open up even more!

For architects, it will mean that within minutes, they will be able to print on screen prototypes of buildings, so they have a tangible product to show the customer, in virtually no time at all!

For retail, 3D printing could mean that shops hold no stock, and products (less complex ones at first, but branching out in the future) could be made to order, on site! No longer would shops be out of stock, so long as they have material to print on, they can make new products, there and then.

For healthcare, the new printing capabilities will mean that body part replacements can be accurately measured, designed, and then printed. Yeah, printed bones! Just last month, it was publicised that the first 3D printed jaw had transplanted onto the face of a woman from the Netherlands. The jaw was matched to the shape of the patient’s original jaw, using CAD modelling, and then layers of titanium powder were melted into shape by the powerful lasers that make up the 3D printer.

How do 3D printers work?

Different 3D printers work in different ways. Some work by building the object slowly, layer upon layer in an upwards direction, whilst others work by cutting down into a material. The titanium jaw example from above was built by building upwards creating layers upon layers of material, from titanium powder fused together by laser.

What materials can be ‘printed’ on?

Currently you can ‘print’ on plastics, metals, ceramics, glass, and even certain malleable foods (such as sugars and chocolate). In the future that selection of materials is likely to be expanded, and some even believe that we could grow human bone, and then 3D print replacements – that is still a way off at the moment though!

Could you get a 3D printer?

Many firms are looking to capitalise on the decreasing cost of 3D printers, so much so that some companies are now offering (simpler) domestic versions for home use!

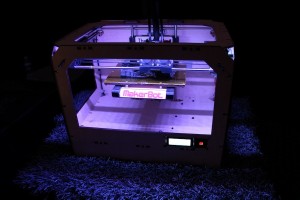

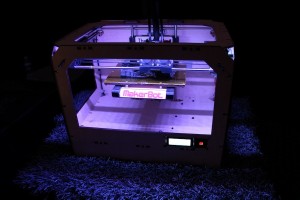

One firm selling 3D printers to the domestic market is the New York company MakerBot. Makerbot are offering a basic 3D printer, which can create plasic objects using CAD software, for $1,749 (around £1,100).

In an interview with the BBC, MakerBot’s chief executive Bre Pettis, claimed that the printer is “a machine that makes you anything you need” which is “handy in an apocalypse or just handy for making shower curtain rings and bathtub plugs.”

In an interview with the BBC, MakerBot’s chief executive Bre Pettis, claimed that the printer is “a machine that makes you anything you need” which is “handy in an apocalypse or just handy for making shower curtain rings and bathtub plugs.”

Mr Pettis also said he hoped to get his printers “into the hands of the next generation because kids these days are going to have to learn digital design so they can solve the problems of tomorrow”.

Another company, (called 3D systems) is offering its ‘Cube’ 3D printers at a similar price to Makerbot, marketing it as a tool to express your creativity. The company is currently working on an app that will allow users to use the Microsoft’s Kinect motion sensor to create objects, simply by moving their hands through the air!

Some of 3D Systems ‘Cube’ printers, prining 3D objects

3D printing is bringing to the global market a fast and increasingly affordable way of turning ideas into reality. No longer will the joys of flexible design be limited to those with CAD jobs and the luxury of a prototype department. There is now a big incentive for people to learn CAD techniques and how to use CAD software. Many countries are now investing in 3D printing technologies, as they can see the potential; IT jobs in the UK and abroad are likely to see big benefits from this.

3D printing is real, and it is here.

So, what do you think about 3D printing, will it revolutionise the way we live our lives – even as much as the internet did? Or do you think that it is a waste of resources, and that it will never really be cost effective enough to be used on a mass scale?